HTS Conductor Processing & Power Application Division

Realizing usable coated conductors and superconducting power devices

Objective

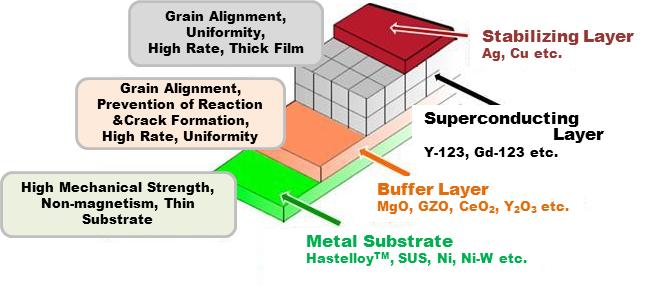

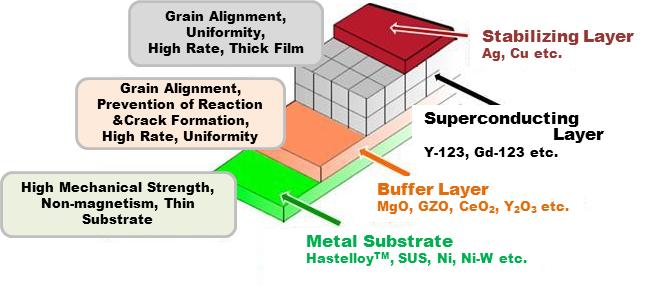

- REBCO superconducting (REBa2Cu3Oy) coated conductors (CCs) could realize large current capacity & high field generation, which are difficult by normal conductors (Cu) and BSCCO silver-sheathed superconducting tapes. Therefore, the light and small HTS devices with the innovative functions including high efficiency could be expected.

In the past, the fabrication processing for long CCs with high performance has been developed in the Superconducting Tapes & Wires Division. Then, long CCs with extremely high level characteristics such as an in-field Ic and a low ac loss have been successfully realized. On the other hand, the application development of the electric power devices such as SMES, Cable and Transformer etc. had been taken place in the Electric Power Equipment Division.

The above two divisions were combined at April in 2013. In this division, further improvement of tape performance, which is necessary for obtaining absolute superiority to the competitive devices, and coiling technology for a new application field such as medical applications have developed now.

|

Themes

- Long CC with high in-field Ic tapes

- Development of long tape processing with the high in-field performance, which is equivalent to the highest value in the short tape at present

- Ultra-low Heat generating tapes

- Development of long tape processing with low heat-generation by improvement of Ic uniformity, filamentation technology and joining with extremely low electric resistance etc.

- Fundamental evaluations of CCs and coils

- Evaluation of Ic-B-T-θ properties, losses, releasing magnetization, mechanical strength of several kinds of CCs and coils.

- Supply of buffered substrates and CCs

- Supply of substrates with well-textured buffer layers and coated conductors with high superconducting performance.

Developimg Methods

- Ion Beam Assisted Deposition (IBAD)

- Deposition of well-textured buffer layer of MgO

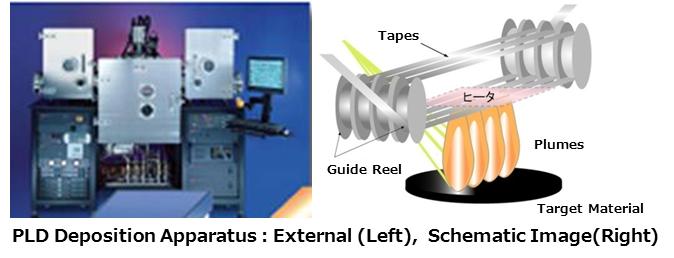

- Pilsed Laser Deposition (PLD)

- Deposition of high performance superconducting layer and CeO2 buffer layer

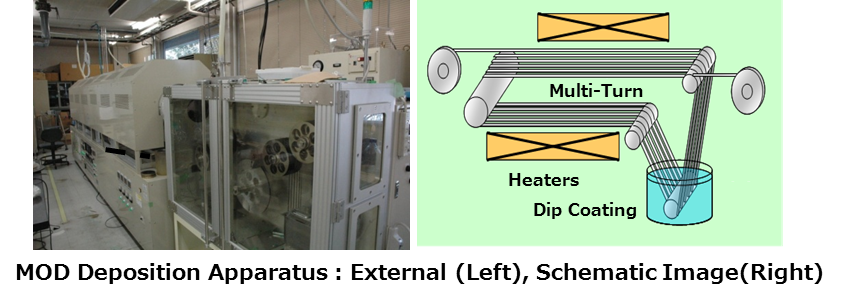

- Metal Organic Deposition (MOD)

- Deposition of low cost superconducting layer

- Cutting, Scribing, Evaluation Technologies

- Laser Cutting & Scribing, RTR Ic measurement, "Tapestar"TM(Hall Probe Method), RTR Magneto-optical observation, SQUID etc.

Main Activities

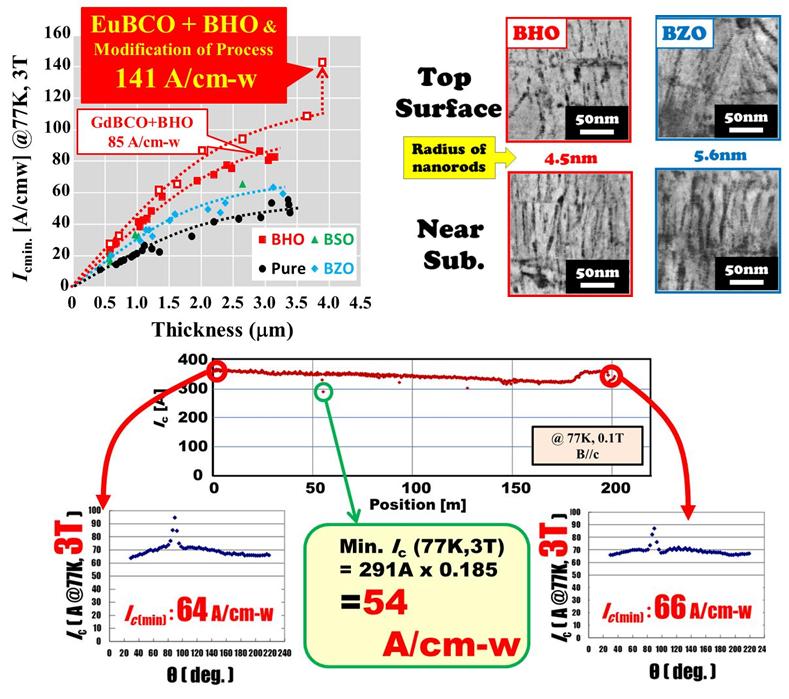

- APC Introduction CCs(EuBCO+BHO) by PLD

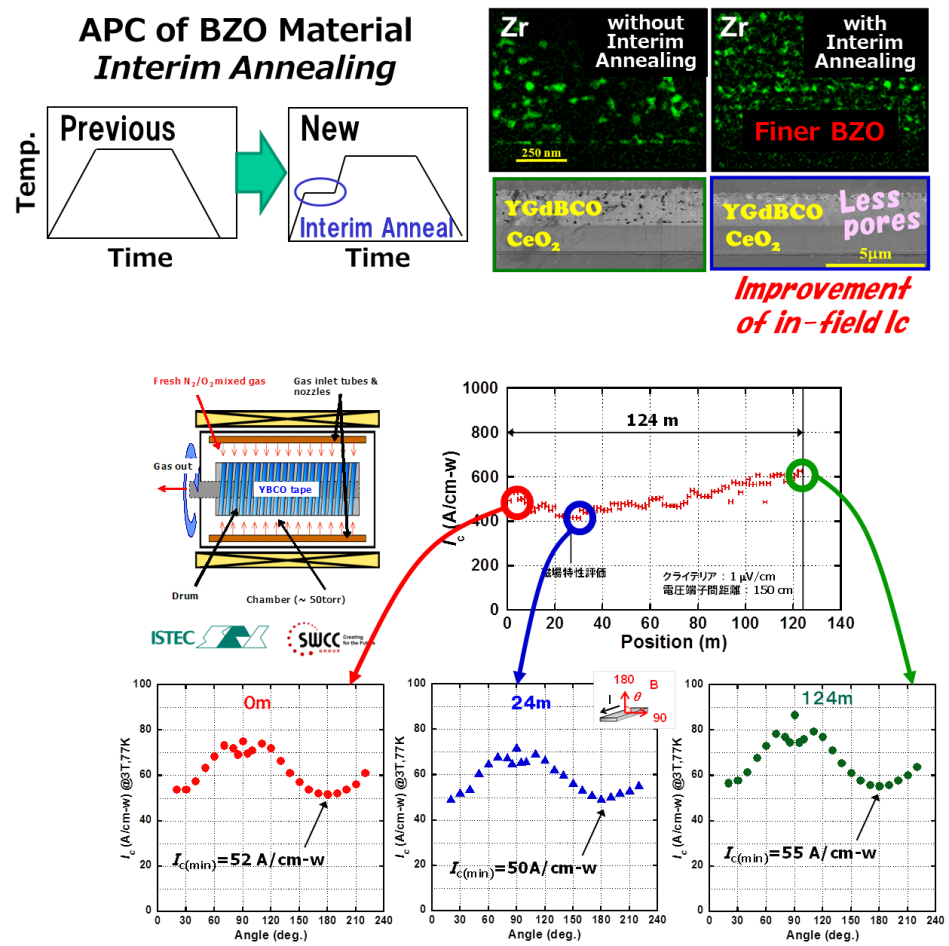

- APC Introduction CCs(YGdBCO+BZO) by MOD

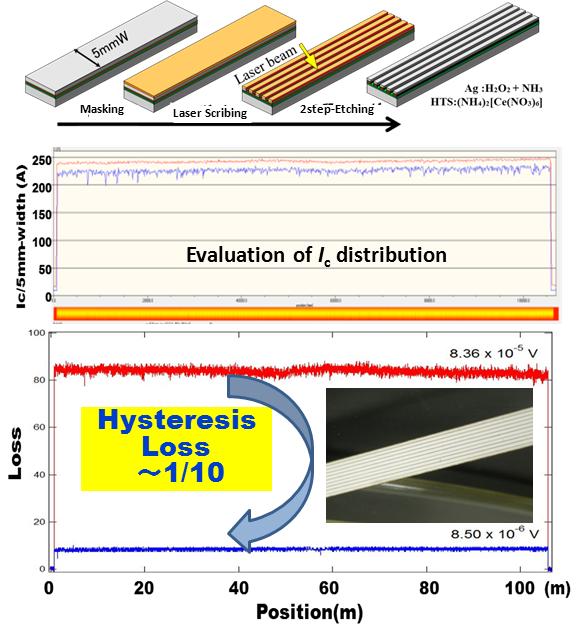

- Low AC loss tape by filamentation

Key paper

- T. Izumi, “Achievements in M-PACC Project and Future Prospects on R&D of Coated Conductors in Japan”, Physics Procedia (2013).

- M. Yoshizumi et al., “Improvement of delamination strength of REBCO coated conductors”, Physics Procedia (2013).

- T. Machi et al., “New filamentarization technique for multi-filamentary coated conductors”, Physics Procedia (2013),

- T. Yoshida et al., “Fabrication of Eu1Ba2Cu3O7-?+BaHfO3 coated conductors with 141 A/cm-w under 3 T at 77 K by IBAD/PLD process.

- Y. Shiohara et al., "Overview of Materials and Power Applications of Coated Conductors Project," Jpn J. Appl. Phys. 51, 010007 (2012).

- S. Miyata et al., "Surface roughness of MgO thin film and its critical thickness for optimal biaxial texturing by ion-beam-assisted deposition," J. Appl. Phys. 109, 113922 (2011).

- N. Sakai et al., "Delamination behavior of Gd123 coated conductor fabricated by PLD," Physica C 471, 1075 (2011).

- K. Nakaoka et al., "Relationship between crystallization process and superconducting properties of YBCO films by TFA-MOD method using starting solution with various compositions," Physica C 470, 1242 (2010).

- Y. Yamada et al., "Long IBAD-MgO and PLD coated conductor," Physica C 469, 1298 (2009).

- T. Izumi et al., "Development of TFA-MOD Process for Coated Conductors in Japan," IEEE Trans. Appl. Supercond. 19, 3119 (2009).

- M. Yoshizumi et al., "High production rate of IBAD-MgO buffered substrate," Physica C 469, 1361 (2009).

- A. Ibi et al., "Development of long REBCO coated conductors with artificial pinning centers by using MPMT-PLD method," Physica C 468, 1514 (2008).

- Y. Shiohara et al., "Japanese efforts on coated conductor processing and its power applications: New 5 year project for materials and power applications of coated conductors (M-PACC)", Physica C 469, 863-867 (2009).

- Y. Yamada et al. “GdBaCuO and YBaCuO Long Coated Conductors by IBAD-PLD” IEEE Transactions on Applied Superconductivity, 17 (2007) p3371

- T. Izumi et al. “Progress in Development of Advanced TFA-MOD Process for Coated Conductors” Physica-C, 463-465 (2007)p510